TATA Best Foods Ltd.

After three decades of performing exceptionally well in Textile domain, the company decided to diversify and branch out in Food and Energy business. The meat is provided by up to the mark slaughtering house setup by TATA PAKISTAN, and the Food/FMCG wing works under the name of TATA Best Foods Ltd.

HALAL MEAT

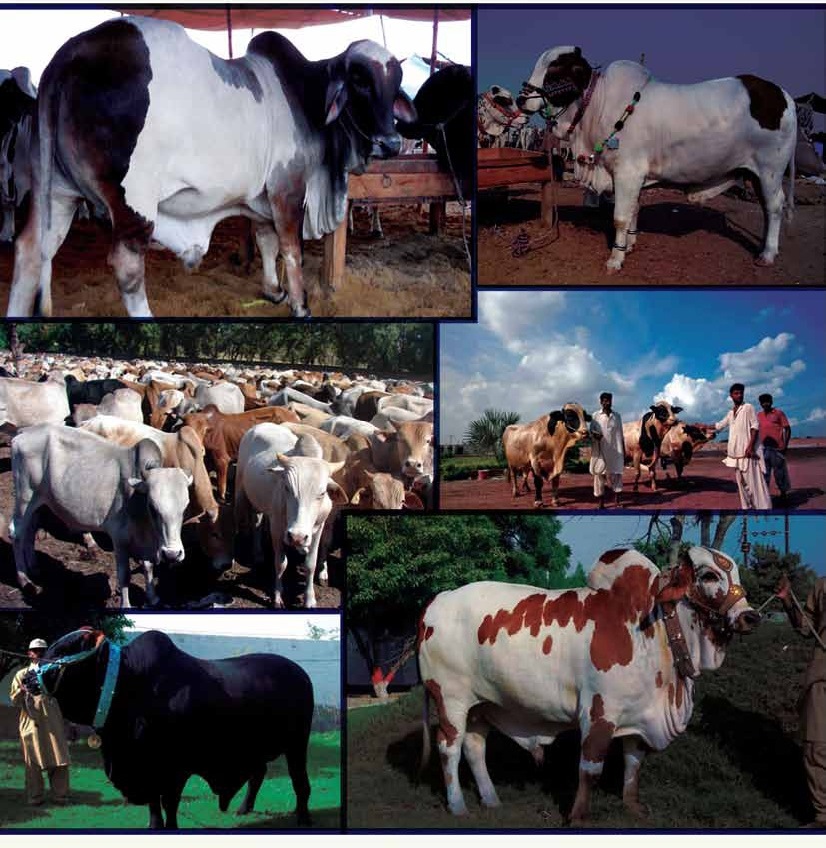

Pakistan is an agri-based country with 70% of its population acquiring sustenance through agriculture and 25% of the land is under cultivation and is supported by one of the biggest irrigation systems in the world.

With the Indus River transcending through Pakistan, it supports much of the agriculture. Almost every constituency in Pakistan has animal husbandries due to the locally produced grain and wheat straw that is easily available. This has allowed the growth of the 8th largest naturally grown livestock herd in the world and has empowered the country be a proud grower of Halal Organic Grass fed Red Meat, developed in natural and stress free environments.

TBF, The Home of Quality Meat, operates in an environment with a diverse agricultural base. From the much cherished buffalo breeds, TBF has the access, expertise and understanding to choose from the best available to offer to its customers. Lamb and goat varieties of Pakistan too are quite varied. Pakistan has a mix variation of breeds depending on the location of the grazing lands in which the herdsmen dwell to naturally band organically sustain their livestock.

GROWERS

TATA PAKISTAN is well-known for maintaining the best cattle and farms in the country. The meat and food products are supplied from the GROWERS established by the group only. Our objective is to sustain stability in price, supply and quality as a Grower. We have the capacity to accommodate sufficient number of cattle to supply red meat to our meat food line. We take pride to stand as one of the finest quality grower in the country.

LAIRAGE / LIVESTOCK

At TBF, health and welfare of our livestock is one of our top priorities. Everything from their living condition to their nutrition is carefully monitored. Our animals receive the best balanced diet, selected from the leading suppliers that are engaged in 100% natural processes.

Our lairage pens are designed to meet international standards for optimal comfort to reduce stress and provide safety to the livestock. The lairage pens have a capacity of 750 cattles, 3,000 goats / lambs. Our pens have 24 hour pre-slaughter observation. All livestock are regularly observed by experienced DVM veterinary doctors. Moreover, the lairage pens have separate areas for quarantine and detention.

HIGHLIGHTS – LIVESTOCK

- Pre-buying Livestock surveys

- Back End Farm Contracting for specialized requests

- Buffer Stock availability for:

- Price stability in volatile Market Days

- Supply stability in Off Season Weeks

- Quality Stability

- Livestock collection center for easy “Direct to Market” facilitation of livestock farmer

- Model Calf/Goat Fattening Farms

- Facilitation of financing of livestock growers

- All live stock checked by experienced DVM veterinary doctors.

HIGHLIGHTS – LAIRAGE PEN

- Capacity – 500 Cattle and 3,000 Goats/Lamb

- Buffer Stock Holding Capacity in Multan – 3,000 Cattle and 10,000 Goats

- Designed as per International Standards for Reduced Livestock Stress and Protection against adverse weather

- Separate Areas for Quarantine and Detention

- Impervious Floors and Passage Ways for easy cleaning and sanitation

Products

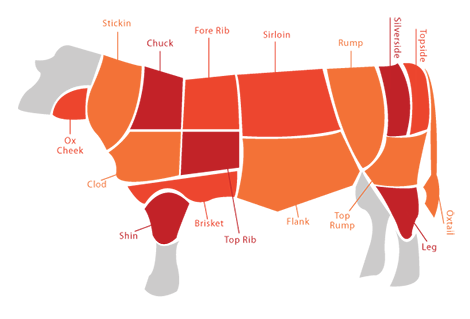

Beef

Packages food is either chilled or frozen, boned or de-boned, or provided in vacuum or carton packaging.

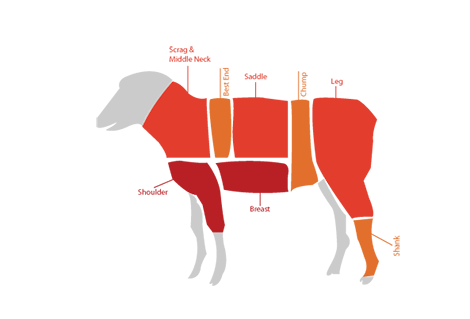

Lamb

Packages food is either chilled or frozen, boned or de-boned, or provided in vacuum or carton packaging.

PRODUCT AVAILABILITY

- Whole Carcass Quarters, Cuts or Compensated Cuts

- Bone-in or Deboned Meat

- Chilled Vacuum / Cotton Packed

- Frozen Carton Packing

PRODUCT RANGE

We meet all your meat needs. Whether you are seeking whole carcasses or superbly cut pieces, we have a wide range for you to choose from.

A-Red Offal

B-Veal

- Cattle Veal

- Buffalo Veal

C-Bovine

- Cattle Beef

- Buffalo Beef

D-Ovine

- Goat

- Lamb

- Fat-Tail Lamb

- Sheep

HYGIENE AND QUALITY STANDARDS

- Sophisticated data capture system installed to ensure traceability from farm to farm;

- Traceability records are maintained in accordance with statutory, regulatory and customer requirements;

- All products whether Carcasses, Sides, Quarters, Cartons or Vacuum Packs are individually tagged and weighed;

- Proper Tagging System is used for Slaughtered and Dispatched Batches;

HACCP IMPLEMENTED

1. Conducted Hazards Analysis

2. Determine Critical Control Point

3. Establish Critical Limits

4. Set up a monitoring system

5. Establish Corrective /Preventative actions

6. Establish SOP for Effectiveness of HACCP

7. Maintain through records

COLLECTION & DISPOSAL OF WASTE

• Waste collection according to Layout.

• Safely disposal to municipal authority through approved Contractor

• Waste Water treatment through Septic Tank (3 distinct zones separation system)

To ensure the absolute strict adherence to the food safety, hygiene, quality, and traceability standards, TBF has embarked on a journey to develop and maintain its facility as an efficient & effective Food Safety Quality Management System (FSQMS) audited on strictest of world’s standards available and though its dedicated team of internal auditors runs regular audits to ensure TBF remains the best and most hygienic facility in the region. TBF is here to service the whole world and will maintain the world class standards to do so.

In this journey, TBF has acquired the BRC certification in JUNE 2013 and maintaining it along with Halal Certification from Malaysian recommended Islamic Body. Some salient features of the BRC attestation on TBF’s FSQMS are:

- Traceability verified

- Food grade equipment and materials

- Hygiene records and implementation of personnel belongings and equipment

- Plant labelling and instructions understandable and visible

- Training and skill review or personnel

- Plant sanitation programs

- Product specification and adherence

- Pest control procedures in place and under implementation

- Complete and functional HACCP plan in place

- Non-conforming product control

- Regular lab testing and equipment calibration

We will keep inviting other firms to try us, test us and audit us for us to remain world class.

LIVESTOCK – ANTE MORTEM

|

|

Actions Taken:

- Quarantine

- Detention

Held till Livestock is showing signs of cure. If not, livestock handed back to supplier

LIVESTOCK – POST MORTEM

- Lungs/Liver/Kidneys/Heart/head

- Green Offals

- Overall Carcass Status

Actions Taken

- Condemnation

Infections, Tumours, Evidence of Carcass Wide Effective Diseases e.g. Anthrax, Pneumonia, Blackleg etc.

- Detention

Hold till lab tests confirm “fit for human consumption status” If Not, Livestock Condemned and disposed to Municipality

PEST CONTROL PROGRAM

- In-house Pest Management System – BRC Standard

- Managed by third party (PESTOP)

We aim to provide consistent eating experiences for our customers by providing top quality meat. We hold ourselves to the highest global industry standards when it comes to quality control.

- 3 Tier Quality Monitoring System

- BRC / IFS / ISO initiative undertaken

- Complete Ante-Mortem, Post-Mortem procedures

- Multiple Quality Tests performed

|

|

We take our hygiene responsibilities very seriously, understanding that nothing undoes flavor, taste and quality. Our staff, personnel and meat practitioners partake in thorough disinfection regimens at every step and process; this includes hand wash, hand disinfection, boot dip and disinfection, as well as boot wash and scrub. We also participate in post slaughter wash and disinfection, and regular swab tests for micro-organism count. Our facilities have in-house sterilization units in the slaughtering line, as well as specialized loading arms to minimize human contact.

WATER HYGIENE

- Regular Microbiological Tests

- seasonal Outsourced Tests

PERSONNEL HYGIENE

- Foot Wash and Scrub

- Hand Disinfection

- Hand Scrubs

- Boot Dip and Disinfection

EQUIPMENT HYGIENE

- Post Slaughter Wash and Disinfection

- Sterilization Units in the slaughtering Lines

- Specialized Loading Arms Minimize Human Contact

- Regular Swab Tests for Micro Organism Count

Sterilization Units in Slaughtering Lines:

- Apron Wash Shower

- Hand Wash

- Knives Sterilization Post Each Carcass Usage

DETERGENT & DISINFECTION USED:

- Hi clean Antibacterial (Hand washing).

- Hi Clean Hand Sanitizer (Hand Sanitizing).

- Target Power Foam & Neomoscan TE-S (Plant Cleaning).

- Vanaquat (Plant Sanitization).

- Chlorine (for vehicle and animal dip tank).

FOOD HYGIENE

- Contact Surfaces Swab Tests

- Special Uniforms to ensure easy hygienic cleanup & disinfection befoer processing

- Post slaughter wash and disinfection

- Sterilization units in slaughtering line

- Specialized loading arms minimize human contact

- Regular swab test for mincro organism count

- All slaughter men are adult, sound minded and well educated Muslims

- Each animal is slaughtered with the recitation of TASMIYA

- Shariah Advisory of TBFL oversees the slaughter men

- Place of slaughtering is used only for Halal Animal Slaughtering

- The knife is cleaned and well sharpened

- After slaughtering 6-8 minutes are given on the bleeding line for ample time for bleed out ensuring completely halal and good quality meat

- Regular trainings imparted on Halal Standards

Halal Meat Markets

Keeping in mind its superb quality and outstanding service, its no wonder that it has managed to find customers in a large number of countries, including

|

Livestock Sourcing

Pre Buying Livestock Surveys

- Back End Farm Contracting for Specialized Requests

- 100% Sahiwal Breed male.

Buffer Stock Availability for

- Price Stability in Volatile Market Days

- Supply Stability in Off Season Weeks

- Quality Stability

Livestock Collection Centers for Easy “Direct to Market” facilitation of livestock farmer

Model Calf/Goat Fattening Farms

Facilitation of Financing of Livestock Growers

All Livestock checked by experienced DVM ante – mortem

Karachi, Pakistan Houses the biggest Buffalo Colony in the world with a population of around 400,000 + buffaloes. This colony is only 1 of 5 colonies in Karachi Alone.

Known for their superior and lean meat, the Dhani and "Cholistani" Breed of Cattle are also best known for their active participation in the traditional Pakistani Race of Bull Racing"

PRODUCTION PROCESS

HALAL SLAUGHTERING (Box-1)

TBF provides 100% Halal quality meat only. The entire slaughtering process is registered by Pakistan Government Authority Animal Quarantine Department (AQD). The slaughtering is only done by a Muslim man. Our Shariah advisory board oversees the entire process and ensures slaughtering is done as per the Halal standards.

SLAUGHTER LINES / ABATTOIR

- Per shift Slaughtering Capacity = 300 Cattle & 2000 Lamb/Goat/Sheep

- Maximum Anti-Bacterium Design

- Sloped Floors for Efficient Drainage

- Polyurethane food safe flooring

- No Metal to Metal Contact

- All equipment is built with 304 SS Hot dip Galvanized

- Free Motion Rails to Ensure Minimum Stress on Meat through Pushing

BLEEDING LINES

Maximum Bleeding Time before Processing Initiation to ensure:

- Blood Free/Smell Free Meat

- Apply the spirits of the Shariah Requirements

There are separate Bleeding lines available for:

- Beef Bleeding Line

- Goat/Lamb/Sheep Bleeding Line

CUTTING / DEBONING & VACCUM PACKING (Box-2)

The daily deboning capacity at TBF is 40 metric tons. Our plant operators & butchers are well trained by European Consultants and we believe in cascading this to the bottom level. Every member implements best practices in the cutting, deboning and vacuum production processes. Temperature and hygiene is closely monitored to guarantee zero contamination, ensuring that quality products are always delivered. Our industrial vacuum allows for air-tight and specialized atmospheric vacuum packing.

CHILLING & FREEZING (Box-3)

Our state-of-the-art freezing and chilling facilities are of utmost importance to produce consistently fresh, healthy and quality meat that meets the EU and USDA standards. Per shift slaughtering capacity is 300 cattle and 2000 Lamb/Goat/Sheep. Chilling facilities which include blast freezers, carcass chillers, cold and frozen storage which can on average hold up to 200 Metric Tons.

HIGHLIGHTS

- Reduced microbiological growth on meat

- Increased shelf life

- Tender meat with preserved flavor

- Efficient design leading to higher value product for the customer

- On site and remote temperature monitoring

- Carcass chillers for beef and lamb having capacity for up to 65 Metric Tons (Beef 60, Lamb 30 MT)

- Cold Storage for chilled and deboned meat having capacity for up to 100 MT

- Blast freezers having capacity for up to 50 MT

- Frozen storage for deboned meat having capacity for up to 200 MT

COLD STORES

Capacity – Beef Cold store:

- Three beef cold stores for beef chilling

- Each has capacity 100 carcasses, total 300

- Total meat chilling capacity 30,000 kg.

Capacity – Lamb Cold store:

- Four lamb/goat cold stores for beef chilling

- Each has capacity 500 carcasses, total 2,000

- Total meat chilling capacity 20,000 kg

Capacity of Frozen Store:

- Total meat product storage capacity 200 tons

OUR INFRASTRUCTURE – MACHINERY

Manufacturers – G M Steel, Ireland

Designed and Manufactured to 100 % EU/USDA Standard Machinery

Conformity with Machinery Directives

- Directive 2006/42/EC

- Clause 4.5.3International Food Standard

- Clause 4.5 in BRC Global Food Safety

- EU Regulation No 1935/2004 on materials and contacts intended for contact with food

- US Code of Federal Regulations Title 21 Part 177.1520

VACCUM PACKING LINE (Box-1)

- POLAR 2-95-400v-3-50 HZ SEALING BAR

- 2 x 1100 MM FRONT and REAR SIDE VACCUM

- PUMP BOSCH (MADE IN GERMANY)

- ORIGNAL HENKELMAN VACCUM SYSTEMS

BLAST FREEZERS (Box-2)

- Manufacturer – FRIGA - BOHN

- Cooling Capacity 82.9 kW

- Aluminum Fans

- Fin Spacing 9mm

- Fan RPM 1500

- Net Weight 1060 KG

- Five Blast freezers total Capacity: 38 Tons

VISIT US

(on field trip request)

Company Information

Quick Inquiry

- +(92) 213-242-6761, +(92) 213-241-2955

- +(92) 213-2426754

- 6th Floor, Textile Plaza, M.A. Jinnah road,Karachi-74000,Pakistan

Get In Touch

CORPORATE OFFICE

TATA Best Food LTD (Plant)

- +(92) 213 – 508 1501 – 6

- HX – 1, Landhi Industrial Area, Karachi, Pakistan

News & Events

CEO Interview ICMA Magazine Nov-Dec-2022

CEO Interview ICMA Magazine Nov-Dec-2022 Kindly click on the below link; http://www.tatapakistan.com/CEO Interview ICMA Magazine.pdf Happy…

The Spin Newsletter Vol 1 June 2019

TATA PAKISTAN corporate e-newsletter titled “The Spin” covers the events and happenings at the Tata Group from January to June 2019.…

Session on Emotional Intelligence

A presentation on Emotional Intelligence was arranged at the Corporate Office. The speaker was Mr. Sirajum Muneer, who is an accomplished…

Breast Cancer Awareness Session at Corporate Office

October is internationally celebrated as Breast Cancer Awareness Month as studies have shown that early detection of breast cancer can…

Kids' Fun Fair at Island Textile Mills

A Kids' Fun Fair was arranged at Island Textile Mills, Kotri on 16th November 2019. All children living in the…

Contact Us

Corporate Office (Karachi)

- +(92) 213-2426740, 745, 750, 755 +(92) 213 – 2412955

- +(92) 213 – 2417710

- [email protected]

- 6th Floor, Textile Plaza, M. A. Jinnah Road, Karachi - 74000, Pakistan.

UAE

UAE Qatar

Qatar Muscat

Muscat China

China Vietnam

Vietnam Malaysia

Malaysia